News & insight

-

Improved technology for making bonding fasteners for composites

09 Nov 2022bigHead has just installed £1M worth of brand new, state-of-the-art machinery, custom made for us by Expert Technologies Group. We worked with Expert to improve the quality of the technology we use to make our bonding fasteners for composites, meaning that we can reduce the time spent on extra-machining and secondary operations. We anticipate a 30-40% increase in productivity, hence…

Read more -

bigHead research on composite panel fastening featured in FAST magazine

13 Sep 2022Lawrence Cook and Oli le Marquand-Brown, our development engineers, are now based at the Innovation Centre in Cranfield Technology Park. During summer 2022, Will Dalrymple, editor of FAST magazine, visited the new premises and spoke at length to Lawrence and Oli. The resulting feature article delves into the reasons for and huge benefits gained through our R&D facility being located…

Read more -

BigHead Development Team now based at Cranfield Technology Park

24 Aug 2022bigHead Bonding Fasteners is pleased to have secured a base for its composite fastening solutions development team within Cranfield University Technology Park, home to nearly 60 science, technology and knowledge-based businesses. Lawrence Cook and Oli le Marquand Brown now occupy an office within the Innovation Centre, a stone’s throw from the University’s Enhanced Composites and Structures Centre. bigHead has a…

Read more -

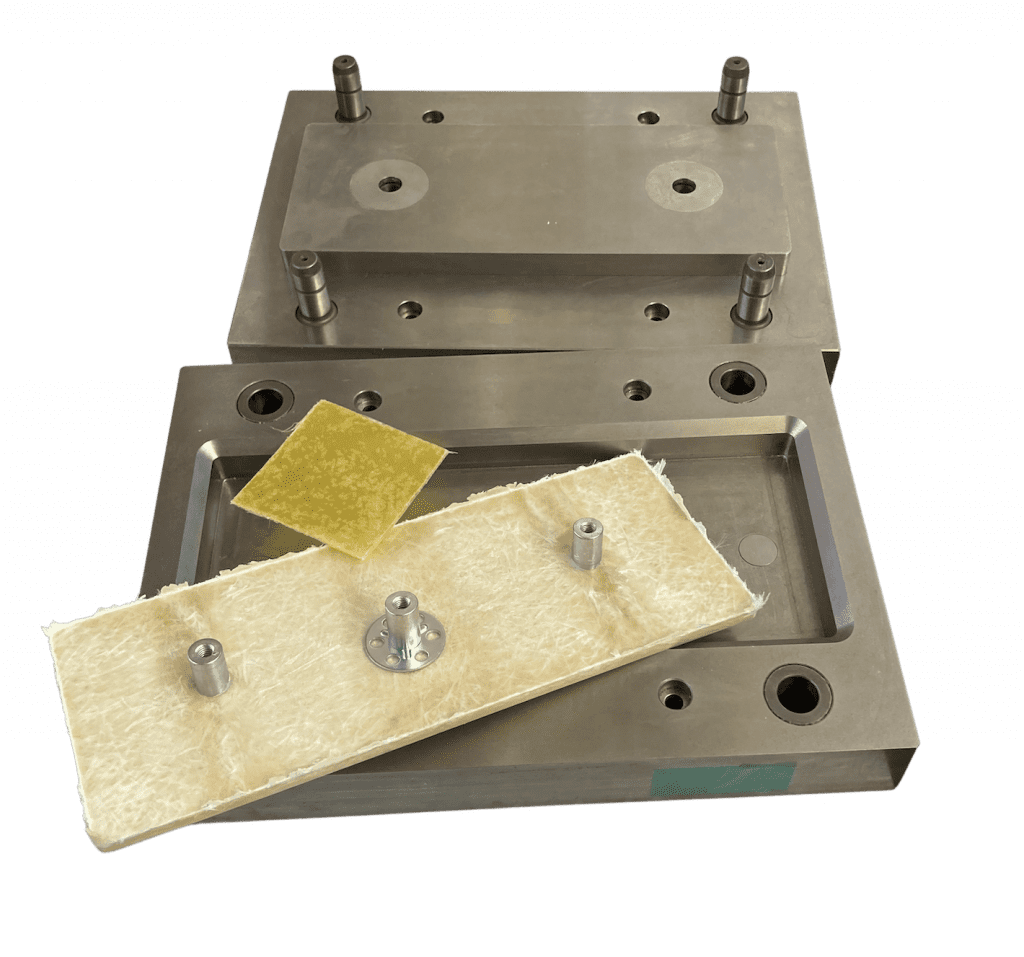

New tool eliminates secondary fixing processes for SMC panel fastening

05 Jul 2022Fastening SMC panels: As part of our R&D partnership with Cranfield University, we have produced a demonstration mould tool that shows how bigHeads can be embedded into that trickiest of materials and processes, sheet moulding compound (SMC), without any ingress of resin into the fixing. Furthermore, our embedding solution is a one-step process that removes the need for any secondary…

Read more -

Solutions and latest innovations for composite material fastening challenges.

23 May 2022The value of talking to industry colleagues face to face was made very apparent at JEC World 2022. Virtual meetings and conferences have been a life-line during recent times but the ability to demonstrate new techniques and let people have a ‘hands-on’experience is invaluable. Thank you to everyone who visited our stand. We gained such a lot from all of…

Read more -

bigHead Bonding Fasteners at JEC World 2022

22 Apr 2022At last – JEC World 2022! May 3-5th. There will be a lot to share and discuss given the three intervening years since JEC World 2019. We know that we have a lot to talk about anyway! Visit our stand to discover our solutions and latest innovations for composite material fastening challenges. As the leading trade show for the industry,…

Read more -

Meet our new Development Engineer

19 Jan 2022We are very pleased to announce that Oli le Marquand-Brown has joined the bigHead® Bonding Fasteners team as Development Engineer. Oli joins from Cranfield University where he was a Research Assistant and completed a master’s degree in Automotive Engineering. Oli conducted extensive research on the use of commercially viable thermoplastic and recycled carbon fibre reinforced polymers and was awarded IMechE…

Read more -

Bossard Group White Paper – insight on the latest developments in fastening composites

06 Sep 2021Fastening composite material presents many challenges, all of which can be overcome by careful selection of the correct solution. There are many solutions and this in itself presents another challenge. Bossard has compiled a White paper on bonding. DOWNLOAD BOSSARD WHITE PAPER ON BONDING Bossard’s White Paper ‘Fastening solutions for composites and plastics’ introduces a selection of technologies and gives…

Read more -

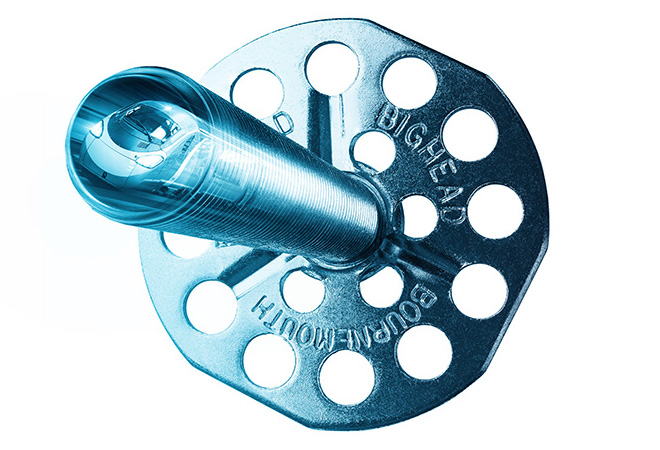

The devil is in the smallest detail

27 Apr 2021You may not consider bigHead composite bonding fasteners as one of your key design tools – but we’d like to argue that they are! They may seem small and inconsequential – until you need to think about joining materials together. Securing the components in your design whilst you try to satisfy multiple conditions probably causes quite a few headaches. Perhaps…

Read more -

Joining in the world of lightweighting

20 Apr 2021Light-weighting no longer means simply moving from steel to aluminium or magnesium. Today’s light-weighted products need structural materials that are lighter still. Wafer-thin sheets of metal, composite materials with glass or carbon fibre, and hybrid structures are the materials that designers increasingly work with. Joining these materials together in ways that meet the design specification can present challenges. Some materials…

Read more