News & insight

-

bigHead benefits demonstrated through animations

23 Mar 2023Our Bossard Group colleagues in Germany have worked with us to create a series of short simple animations which can portray the key benefits of bigHead fasteners in less than 30 seconds. These illustrate the four points below. Why bigHead fasteners reduce the need for localised thickening How a bigHead fastener is invisible from the A-side Using bigHeads for co-process…

Read more -

bigHead business investment strategy featured in JEC Show Magazine for JEC World 2023

22 Mar 2023Our blog article ‘Merits of a long term investment strategy‘ has been published in the special ‘Show’ edition of JEC Magazine, ahead of JEC World 2023. The April/May 2023 issue is focused on turning challenges into new opportunities. Composite materials will play a major part in solutions for a more sustainable future across all industry sectors – automotive, aerospace, marine,…

Read more -

Blue Hearts Embassy for Ukrainian refugees

17 Mar 2023As part of the Bossard Group of companies we are really impressed by the ‘Blue Hearts Embassy’, established by our Bossard colleagues in Poland to support the people of Ukraine, disrupted and displaced by the ongoing war with Russia. The Blue Hearts Embassy is a safe haven and community hub in Cracow, for children, adolescents, mothers and elderly Ukranian refugees….

Read more -

JEC World 2023

13 Mar 2023We are looking forward to discussing composite material fastening issues at JEC World 2023, the trials, challenges and successes. bigHead will be on the Bossard Group stand. We provide fastening solutions that encompass design, process and assembly. Our experience and insight is always enhanced through our talks with visitors at JEC World. Hall 5 Booth S 57.

Read more -

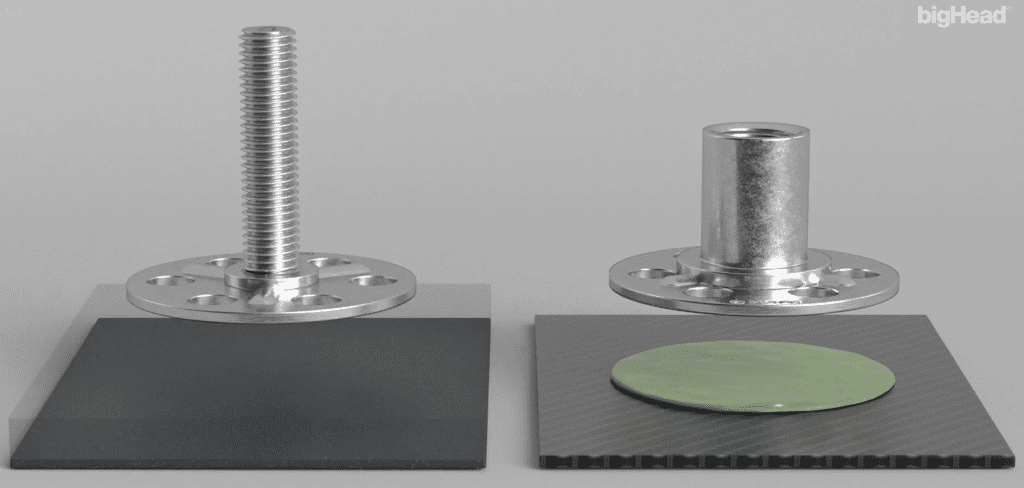

Fastening for core strength

21 Feb 2023Stunning super-car, all electric Rimac Nevera. Lightweight carbon fibre monocoque construction. Strong and powerful. Core fastening strength provided by bigHead fasteners for composite materials. We always feel very proud that bigHead fasteners, such small components, are instrumental in the realisation of incredible engineering design. Get in touch to see how bigHeads can be the solution to your own innovative designs.

Read more