News & insight

-

Global manufacturing needs global support.

13 Apr 2021At bigHead we find that global projects increasingly follow a familiar pattern; design and development in Europe where costs are high, transition to China for volume production. Such global manufacturing is complex, requiring not just the accurate transfer of knowledge and expertise but the management of different cultures and expectations. As part of the Bossard Group, bigHead is well placed to ensure that…

Read more -

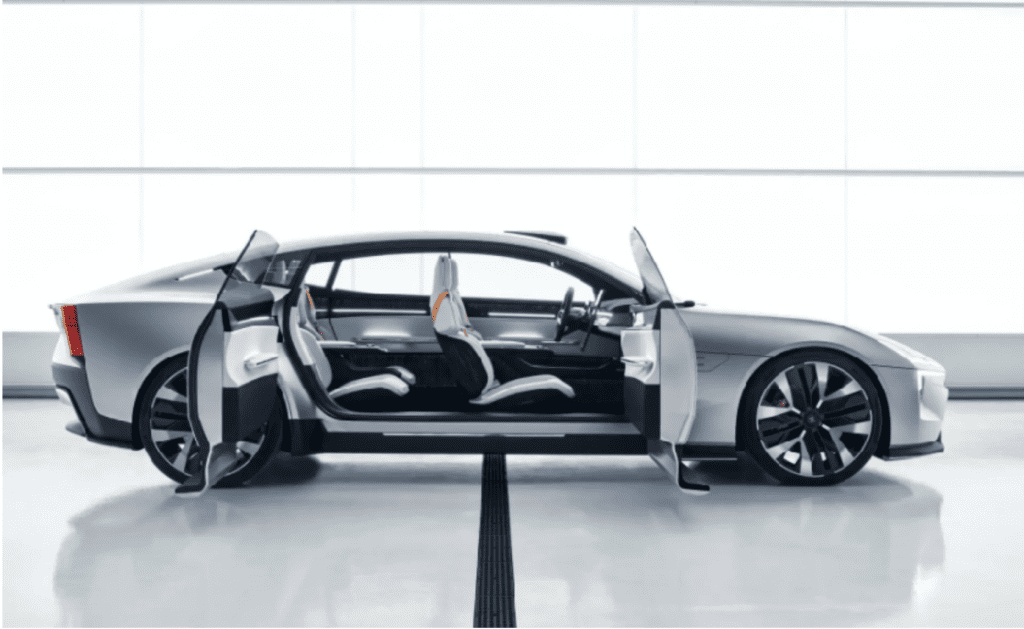

Joining in Car Body Engineering 2021

29 Mar 2021We are looking forward to presenting bigHead Lean Bonding at ‘Joining in Car Body Engineering 2021 –Detroit meets Bad Neuheim’, 19-22nd April. We will be presenting an exciting Lean Bonding update – Lean Bonding PP – together with Powdertech Surface Science. Joining technology is at the centre of technical discussions as the automotive industry transforms and embraces advanced mixed material concepts. Both the US and European conferences will take place virtually, forming an all-virtual Automotive Circle Joining in…

Read more -

bigHead achieves carbon neutral status

25 Feb 2021bigHead is very pleased to have achieved carbon neutral status for 2019 and 2020! We started to focus on sustainability in 2019 and at that point we had no idea what our carbon footprint was. Now we are now measuring it and doing something about it. bigHead is starting to take responsibility for its part in the climate crisis. Finding ways to reduce emissions In 2019 we…

Read more -

bigHead releases Core range technical guide

06 Feb 2020bigHead’s latest innovation, Core range, now comes with a Technical Guide that provides information critical to composite applications: Performance data to help you confidently select the right product for the application Design guidelines to ensure the product is correctly designed-in Assembly features to prevent joint failures For more in depth assistance, please get in touch. bigHead is always ready to…

Read more -

bigHead® expands its innovation team

22 Aug 2019bigHead® Bonding Fasteners continues its investment in innovation with the appointment of two more engineers. Central to bigHead’s strategy is the long-term investment in engineering expertise and composites knowledge. Having received an outstanding report earlier this year from Innovate UK for a KTP with Cranfield University, bigHead has now built a team dedicated to meeting their customer’s most challenging problems. …

Read more -

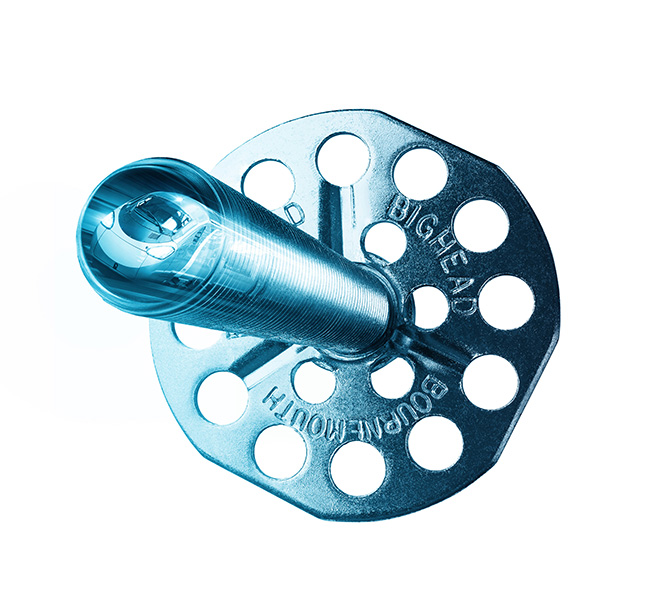

Perforated or Plain Head? A comparison of “wet” adhesive bonding with Perforated/ Plain bigHeads

09 Oct 2018DOWNLOAD WHITEPAPER The Perforated Head design is synonymous with bigHead® fasteners. Whilst this makes a bigHead® easily recognisable, we can also provide bigHeads with Plain surface Heads to suit certain applications. When it comes to adhesive bonding of bigHeads with liquid and paste adhesives, there are long-standing questions about which is actually “better” – Perforated or Plain Head? Holes or…

Read more -

Adhesive bonding and anti-corrosion coatings

21 Jun 2018DOWNLOAD WHITEPAPER Applying anti corrosion coatings, plating or other treatments to bigHead fasteners means that one is no longer working with a steel substrate for the purposes of adhesive bonding. Whilst a selected adhesive may be excellent for bonding steel, it may not be so compatible with different coatings or treatments. Sometimes the coating or treatment itself can also…

Read more -

bigHead® invests in innovation with the appointment of Dr Lawrence Cook

06 Feb 2018bigHead® Bonding Fasteners continues its investment in innovation with the appointment of Dr Lawrence Cook. Dr Cook joins bigHead from Cranfield University Enhanced Composites and Structures Centre where he was a Research Fellow in Composites Manufacturing. During his time at Cranfield Dr Cook worked on the design, manufacturing and mechanical testing of composites structures, in particular the joining of polymer…

Read more -

bigHead® tackles challenging composite fastening applications at JEC World 2018 – Hall 6, Stand E45

24 Jan 2018bigHead® returns to JEC World 2018 this year with design engineers on hand to discuss composite fastening applications. The emphasis will be on engineering solutions that avoid the typical compromises between form and function, and ways to improve process efficiency. Most recently bigHead has been developing a new way to fasten lightweight automotive panels in just seconds, called Lean Bonding®. …

Read more -

Fastening solutions for the rail Industry: bigHead® provide economic and efficient fixings for FRP panels and components

24 Oct 2017Just as other major global industries, mass transit continuously strives to improve manufacturing efficiency and reduce running costs. For rail vehicle and passenger coach designers this has meant embracing new materials and production techniques, and one area that continues to thrive is the use of fibre-reinforced polymer composites (FRP) materials to produce structures and parts that are lightweight, have high…

Read more