News & insight

Integrating fasteners into closed mould production processes.

We’re delighted to announce that our 2023/24 student project is in full swing at Cranfield University’s Enhanced Composites and Structures Centre. Under the guidance of our development team, based at the Cranfield Innovation Centre, and Andrew Mills, principal research fellow in composites manufacturing at Cranfield University, this project builds on our continued research into integrating bigHead fasteners into closed mould production processes. Importantly, by directly incorporating the fastener in the component manufacturing process, the need for secondary fastener installation operation is eliminated, enhancing production efficiency and maximising production through-put.

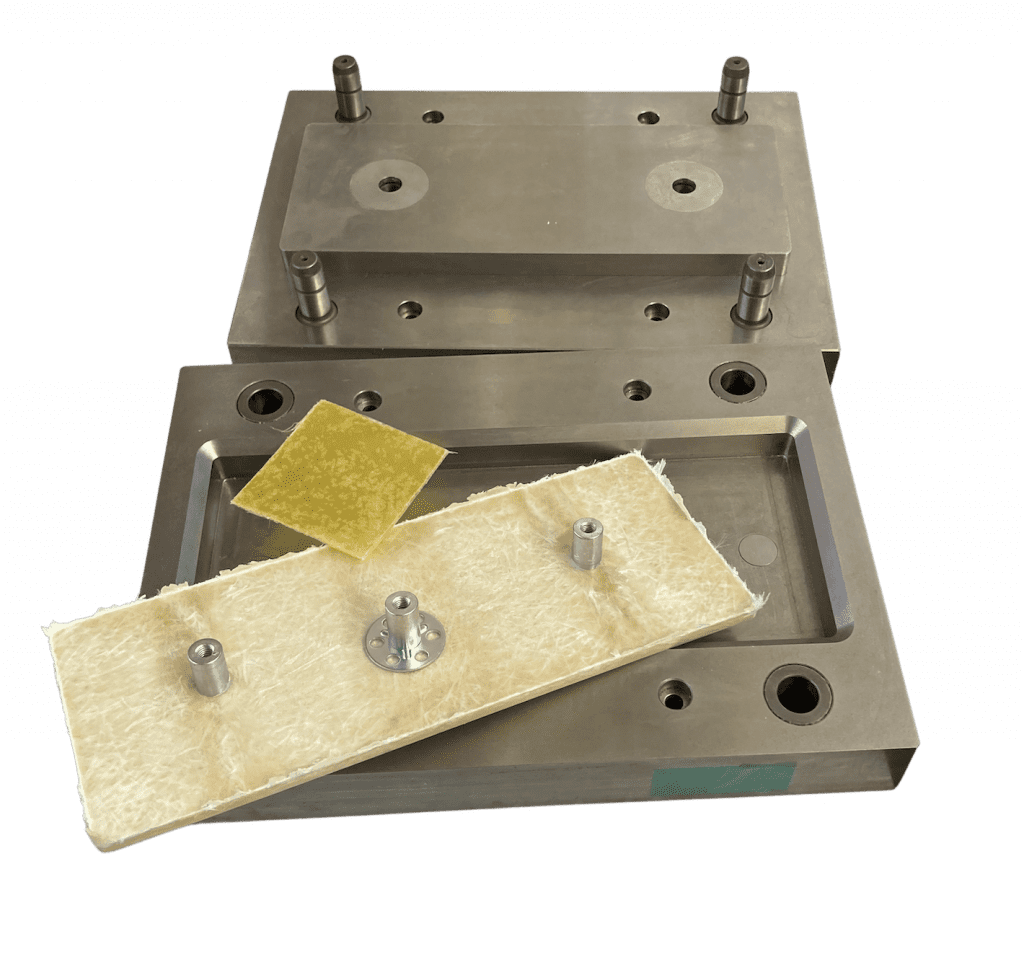

This 2023 student project marks the latest collaboration between bigHead and Cranfield University’s composites centre, building on the success of two previous student projects in 2021 and 2022. Through these previous projects, we’ve developed a demonstration compression moulding tool showcasing how bigHead fasteners can be embedded within sheet moulding compound (SMC) without risk of resin ingress into the fastener fixing. We’ve also studied how SMC flows around the bigHead fastener within the mould and how altering the placement of the SMC affects this material flow behaviour.

We’re committed to furthering our knowledge and understanding in this area through collaboration with this year’s student. Together, we’ll investigate strategies for mitigating against localised moulding defects such as knit lines and voids. Our experience of working hand-in-hand with the students at Cranfield University consistently proves to be positive and enlightening, contributing to our collective growth and innovation.