News & insight

Joining in the world of lightweighting

Light-weighting no longer means simply moving from steel to aluminium or magnesium. Today’s light-weighted products need structural materials that are lighter still. Wafer-thin sheets of metal, composite materials with glass or carbon fibre, and hybrid structures are the materials that designers increasingly work with. Joining these materials together in ways that meet the design specification can present challenges. Some materials are non-threadable and cannot be drilled. Some are so thin that there is no room for embedding a fastening point and others cannot be welded. Structural loading and torque-up may need to be considered. It’s a steep learning curve for design engineers.

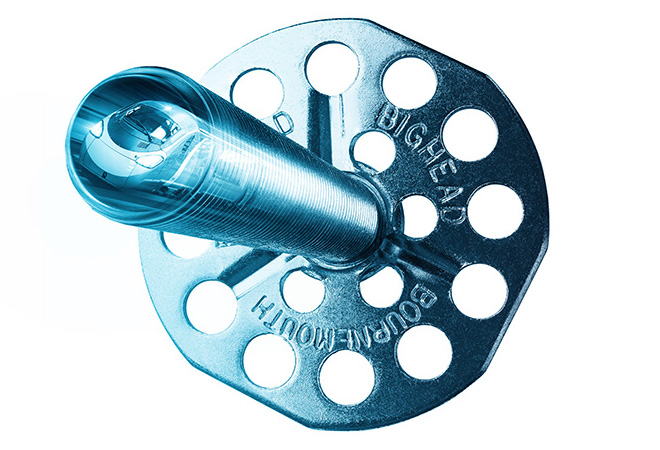

This is where bigHead Bonding Fasteners’ 50 years’ experience in solving fastening challenges can make that journey easier. We will work with you from the outset to advise on suitable fasteners and design bespoke fastenings where necessary. We will help with process optimisation as new materials frequently dictate new processes. Our experience will mean that you avoid common mistakes, can refer to our technical reports and have no need to carry out trials and tests yourself. With bigHead in the wings, joining for lightweighting can be resolved, your design concept need not be compromised and you can be confident that your vision will be achieved.