Fastening Points

JEC 2023 notable trends in the use of composite materials

What did we see at JEC 2023?

In the realm of composite materials, the JEC World exhibition serves as a pivotal and accessible annual platform, offering a vital glimpse into the vast array of emerging technologies and trends within the composites industry. For bigHead our focus revolves around securely fastening components made from composite materials. We actively participate in countless discussions, both at our stand and elsewhere, sharing knowledge and attentively listening to stories of successful fastening methods and the challenges encountered. This enables us to ensure that our ongoing development endeavours remain pertinent and guided by industry demands.

At JEC World 2023 we noted four significant areas in which the industry is concentrating its efforts. As might be expected, these are not mutually exclusive.

Manufacturing technologies for composite materials

Examples of SMC (sheet moulding compound) compression moulding were prominent, with applications ranging from automotive body panels and under vehicle protection to seat reinforcement structures for flying vehicle prototypes. There was a specific focus on the use of SMC for battery enclosures, with multiple material manufacturers focusing development on materials which can meet stringent flame retardancy and toxicity regulations.

Fasteners can be integrated into the SMC compression moulding process; however, this is notoriously challenging due to the low viscosity of SMC.

bigHead has developed a demonstration mould tool showcasing how bigHead fasteners can be embedded within SMC mouldings, without any resin ingress into/ around the fixing. This embedding solution is a one-step process that removes the requirement for secondary fastener installation processes, such as drilling or punching. Contact us to find out more about our work in this area.

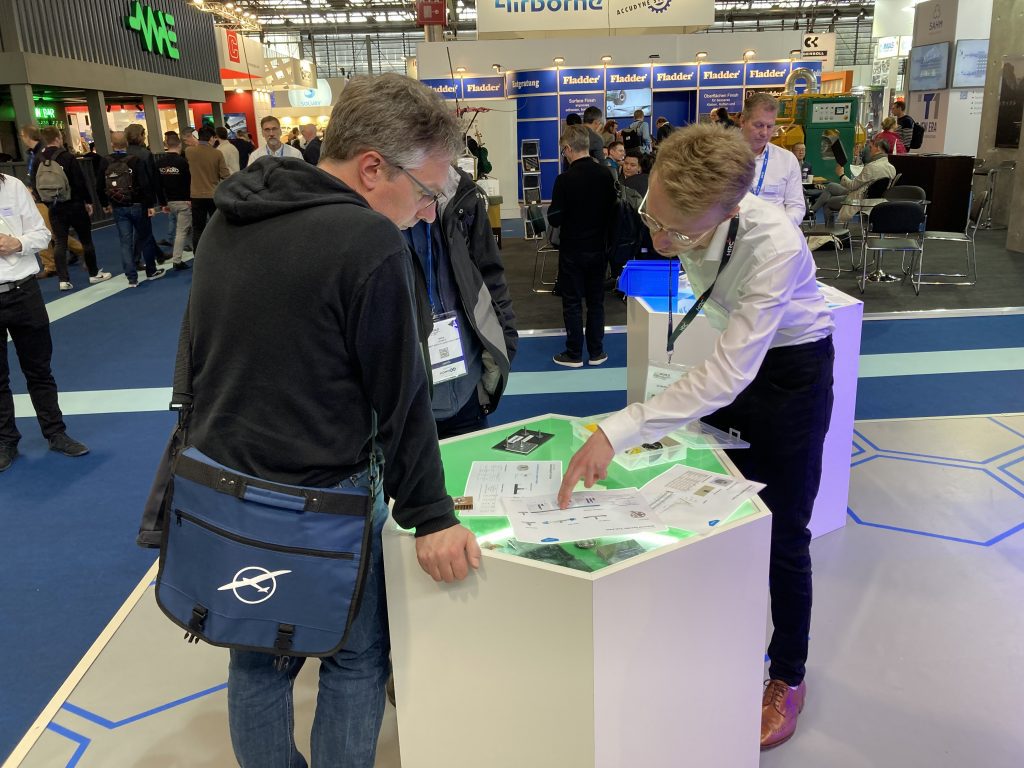

bigHead’s Oli le Marquand-Brown explaining composite material fastening options

Composite material manufacturing processes adding layers of complexity

It was very clear that composite component manufacturing processes are growing increasingly complex. Several examples we observed at the show combined various composite forms and manufacturing processes to form a single component.

An example of this was the Toyota Tundra seat frame exhibited by L&L products and BASF. This seat frame consists of a continuous glass fibre reinforcement beam and discontinuous fibre reinforced seat structure and was manufactured in a 3-stage process: pultrusion of the continuous fibre beam, injection moulding of the reinforced seat structure, and finally injection over-moulding of the reinforcement beam and seat structure.

Over-moulding was prevalent throughout the show, with complex front end module designs realised through the process. Front-end modules manufactured in this way demonstrate a substantial reduction in overall component numbers, reducing time expenditure associated with the assembly of such components.

Each composite form and manufacturing process requires specific consideration when it comes to selection of suitable fastening technologies. bigHead understands the challenges that working with these materials and processes pose and can help identify the optimal fastening solution for an application.

Applications for additive manufacturing are growing for composite materials

Additive manufacturing (the process of creating an object by building it one layer at a time), widely known as 3D printing, is gaining momentum within composite manufacturing.

9T Labs demonstrated one such technology, wherein a near net shape composite component is 3D printed in its entirety (polymer matrix and fibre reinforcement). After 3D printing, the composite component possesses a high void content and is therefore subjected to a compression moulding process. This compresses the component into its final geometry and reduces the void content. This is another instance of multiple processes being combined to form a single component.

At present additive manufacturing is aimed primarily at medical & aerospace applications, as the process permits the flexible production of intricate designs that are otherwise challenging to manufacture using traditional methods. Since the structure is built up in layers, there is also typically less material waste associated with additive manufacturing compared to alternative manufacturing processes. It is anticipated that migration into automotive design will grow over coming years as the process becomes better suited to higher production volumes.

3D printing technology working with composite material

Composites industry increasingly focusing on environmental aspects

As would be expected, the composites industry is actively addressing the environmental implications of its products and processes, both where they can help and where their effects should be mitigated. Sustainability was a hot topic at the show, with bio-composites and recycled materials being prominent. Several of the conference programs were dedicated to recycling and sustainability.

The advantages that composites can offer in terms of reducing CO2 emissions and energy consumption by lightweighting, and also in ensuring long lasting performance and durability, are significant. Efforts to work with natural fibres is gaining momentum as is the development of resins and polymers that are either bio-based or can be reclaimed at the mouldings end-of-life.

Increased understanding and awareness in the composite materials marketplace

With the necessity to re-imagine many of their traditional concepts and designs in composite materials rather than metal, many engineers are becoming more technically aware of what is possible. Given the plethora of materials and moulding technologies available, close guidance on the optimum solution for fastening and securing components within these designs is now more critical than ever, to avoid frustration, delays and wasted expense. In our TecHub we have guidance documents available for downloading.