Fastening Points

Composite panel fasteners for automotive applications

bigHead® Bonding Fasteners help provide fast, secure and cost-efficient results

As composites are used for a wider range of automotive applications, the importance of composite panel fasteners grows. The creation of secure and reliable fastening points compatible with a wide range of composite materials and their different fabrication processes is key. bigHead helps designers and fabricators meet these challenges in several ways.

Design together bigHead works with stakeholders early in the design process to ensure all the details are understood and the requirements met. We work with OEMs to check final assembly loading requirements and we work with tier suppliers to make sure that dimensional tolerances are compatible with mould tools, for example.

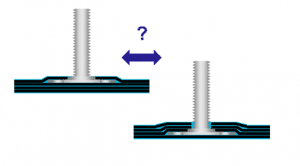

Versatile Some designs might require a composite panel fastener to secure a very thin panel with a fastener that is completely invisible from the A-side. Other designs might require a fastener that is embedded in the composite panel during the panel moulding process. bigHead has both surface bonded and embedded designs to fulfil both options, without compromising the final design or assembly.

Simplification By understanding the customer’s application in detail bigHead can simplify the fastening selection process and its implementation. With over 50 years’ experience in making composite panel fasteners, bigHead’s expertise and guidance saves significant time and costs.

How are bigHead composite panel fasteners used?

There are two main ways that composite panel fasteners can be installed; by surface bonding after the panel manufacturing process, or by embedding during the panel manufacturing process:

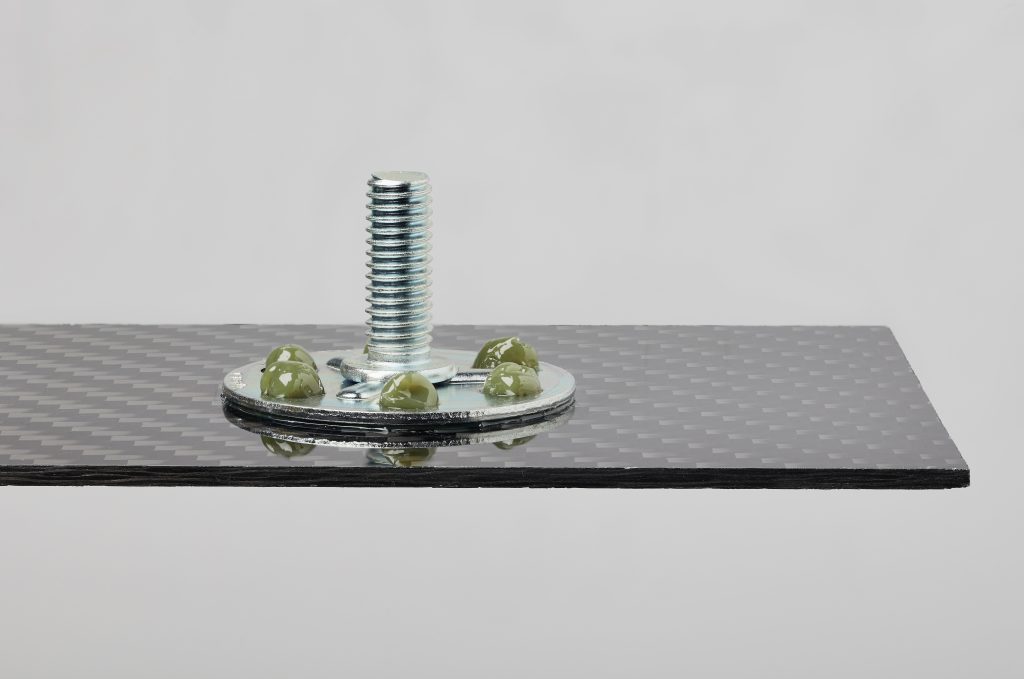

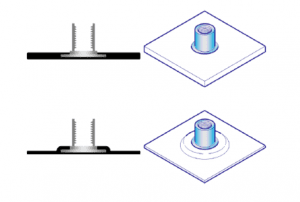

Surface bonded solutions

For materials that are too thin to accommodate an embedded fastener, or for manufacturing processes that prevent the inclusion of a fastener, bigHead’s surface bonding fasteners are an ideal solution. Most often these are surface bonded with adhesives.

This technique offers multiple benefits:

Versatile installation of panel fasteners:

- The fastener can be bonded after the composite part has been manufactured, so it is not restricted by the composite manufacturing process.

- The fastener can be bonded from one side only, so is ideal for situations where only one side is accessible

- The fastener can be designed to fit the bonding area available

- The fastener “Head” can be increased to withstand higher loads, or reduced to minimise weight

- The fastener “Head” is compatible with almost all standard adhesive technologies

- The fastener “Head” can be adapted to offer bond-line control or other features to optimise surface bonding

- The bonding process can be automated for high volumes or done manually for small volumes, making the solution ideal for prototype development to production.

Discrete fastening:

- The composite panel only displays the panel fastener on its bonding side.

- With the correct adhesive selection, surface bonding prevents any witness marks or shadows on the visible surface

Secure fastening:

- Securely bonded into position, a bigHead helps spread the load into the composite panel. Larger Head sizes can increase the load to failure rating of the fastening.

- Adhesive bonding of the composite panel fastener prevents any working loose through vibration.

Economic solution:

- Surface bonding a bigHead to a composite panel can be done manually at a very low cost without complex or expensive tooling.

- For automated solutions, fast curing adhesives and dispensing solutions are available to achieve economies of scale.

No damage to the composite panel:

- Surface bonding of the panel fastener to the composite panel does not weaken the substrate. The fibres reinforcing the panel are not broken or cut and the inherent strength of the panel is maintained.

- Punching or drilling through a composite panel can weaken the structure leading to fastening failure or working loose.

Here are some typical applications for surface bonding fasteners on automotive composite panels:

- Carbon fibre body panels

- Rear end diffusers

- Carbon fibre monocoques

- Carbon fibre chassis

Guidelines for using surface bonded composite panel fasteners

bigHead has developed simple guidelines, available in the tecHub on their website, to help installers and designers avoid assembly errors and problems.

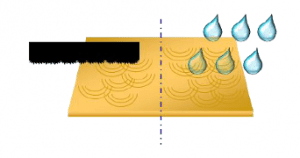

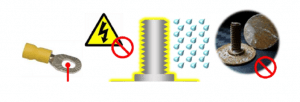

Surface preparation and cleaning:

- The exact requirements vary between adhesives, but our general advice is to take necessary steps to remove any dust, moisture, release agent or other contaminants from the component surface prior to bonding a bigHead in place. Abrasion is not always necessary, but cleaning is always recommended.

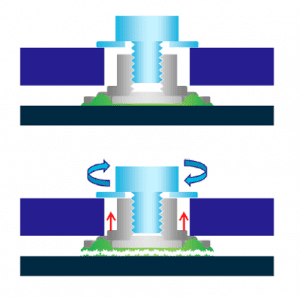

Beware of assembly gaps

- The tightening forces generated during assembly can be enough to separate an adhesively bonded bigHead panel fastener from the component surface. To avoid this, especially in cases where there are gaps between the fastened components, ensure that tightening torques do not create resultant forces above the tensile load capability of the adhesive or the bigHead.

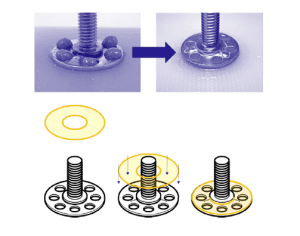

Controlling adhesive overspill:

- Large lumps of adhesive spilling out of perforation holes can interfere with assembly and increase adhesive wastage. To stop this, we recommended considering the application of a thin (50~100 μm) transparent self-adhesive film on the upper side of the bigHead prior to bonding. We do this with our test specimens, and we are happy to advise on suitable cutting sizes.

Be aware of factors that affect the adhesive performance and proper cure

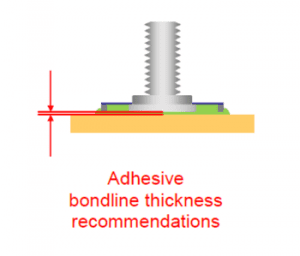

- Adhesives generally have an ideal bond-line thickness for achieving proper cure and optimum mechanical performance – be sure to maintain this and observe the adhesive manufacturer’s recommended cure parameters when bonding bigHeads.

- Carbon steel bigHead products are supplied with a Zinc electroplate finish, which can interfere with the cure of some adhesive products – always check adhesive compatibility or perform tensile tests on bonded bigHeads to determine compatibility.

More information can be found in downloadable guide documents for adhesive solutions in our tecHub

Embedded solutions

bigHead composite panel fasteners can be embedded during the moulding process. A wide range of composite moulding processes and materials are well suited to this type of composite panel fastening.

Embedded solutions offer a number of specific benefits.

Simplification of the process:

- Integrating the panel fastener in the moulding process, or co-processing, simplifies the creation of fixing points on the composite panel. Once moulded, the composite panel has its fixing points for fastening already in place. No secondary operations to bond, drill or punch a fixing point into position is required. The composite panel is complete and ready to fasten.

Precise location of the fastener, every time:

- Located in the mould tool, the fasteners subsequent position in the moulded composite panel is precisely repeated every time. This makes final assembly more precise and reliable.

Secure fastening:

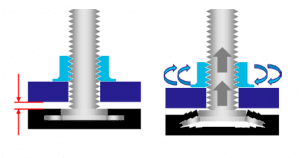

- The bigHead is designed to securely integrate with the composite materials as they flow during the moulding process, effectively locking the composite panel fastener securely into position.

- The Head design can be adapted to increase the integration of the panel fastener in the composite material. Features can be included to prevent material shrinkage creating weak spots through inconsistent material distribution.

Discrete fastening:

- The embedded panel fastener is only visible from the fastening side of the composite panel.

Economic solution:

- Embedded composite panel fasteners can be automated in high volume applications, making this an economic choice for automotive applications.

- The absence of secondary fastening operations makes the embedded solution cost effective.

- The repeatedly precise location of the embedded fastener directly from the composite panel mould tool is lean and very cost effective.

Guidelines for using embedded composite panel fasteners

bigHead has developed simple guidelines, available in the tecHub on their website, to help installers and designers avoid assembly errors and problems.

We refer to embedding as co-process integration; the embedded bigHead and the component materials are processed together within the principal manufacturing or forming process. This ensures the bigHeads are mechanically interlocked into the component material and eliminates the secondary operations associated with post-process fastener installation.

Beware of assembly gaps

- The tightening forces generated during assembly can be enough to detach a bigHead from the component surface. To avoid this, especially in cases where there are gaps between the fastened components, ensure that tightening torques do not create resultant forces above loading capability of the embedment material or the bigHead.

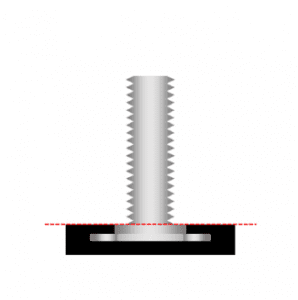

Material shut-off line

- A material shut-off against the shoulder face on the bigHead can help ensure adjoining parts clamp against the metallic shoulder material of the bigHead – not the surrounding material. This reduces the chance of overloading the welded bigHead fixing/ Head joint during assembly tightening and can help prevent issues with creep relaxation of tightened assemblies.

Embedment height effects

- You will probably see the biggest benefit to deeper embedment of the bigHead in a tensile loading, or pull-out condition – in shear and torsion loading conditions, deeper embedment may not increase loading capability.

Embedding into thicker (>3mm) or thinner (<3mm) section materials

- With closed mould processes, encapsulation of the head in a pocket of material is possible.

Beware of electrical and galvanic corrosion implications

- This is especially important when embedding bigHeads into materials with carbon reinforcement materials or pigments.

More information on embedded solutions is found in detailed downloadable guides in our tecHub.

Summary:

When it comes to composite panel fastening for automotive and related applications bigHead fasteners offer a wide range of benefits that help designers and process engineers avoid compromises and achieve optimal results.

With over 50 years’ experience of designing and manufacturing composite panel fasteners the bigHead team can also offer valuable guidance and advice to fabricators.

bigHead is part of the Bossard group of companies.