Fastening Points

bigHead expertise in composite material fastening central to electric vehicle manufacture

bigHead is playing a significant role in supporting Bossard’s Global Electric Vehicle (EV) Group which concentrates on the component fastening requirements of electric vehicle designers and manufacturers across Bossard’s worldwide marketplace. With a presence across four of the world’s five continents, Bossard has established this EV sector focussed initiative with the most relevant group members and brand partners from different locations.

EVs moving into mass production

The Global EV Group met recently in Austria to address electric vehicle manufacturing, with bigHead fronting the discussions related to fastening techniques for composite materials. Composites now play an ever-increasing role in the manufacture of EVs, presenting a range of fastening challenges in which bigHead has great experience and knowledge.

From bigHead’s innovation team based at Cranfield, Oli le Marquand Brown was our representative at this gathering, imparting all we already know and are continually learning about fastening composite materials securely and through ‘Lean Manufacturing’ processes. With increasing numbers of EV models moving into mass production, this creates a growing emphasis on maximising cost efficiency and production rates. Enabling swift and accurate fastening within large automated systems becomes critical. In finding solutions, the bigHead team considers the entire production process from design to final assembly and has the breadth of knowledge required to discuss solutions with engineers in all of these fields.

Composite materials have many structural benefits for EVs

Composite materials have several advantages that can be exploited when utilised in electric vehicle applications. The most widely publicised of these being the excellent mechanical properties and low density possessed by such materials, making it possible to produce incredibly lightweight structures. A lighter vehicle uses less energy and subsequently has lower carbon emissions per kilometre, whilst the driving range is also increased. Various forms of composite materials are being used for an increasing range of vehicle components. In the past, the high cost of using composite materials restricted their use to low volume and high performance vehicles. However, reduced costs are becoming apparent as composite suppliers are integrated into automotive supply chains. This, along with the potential for simplified assembly operations due to reduced overall component numbers and increased modularity compared to metallic structures, means composite materials are an increasingly attractive proposition for use in high-volume vehicles.

Graphic of an electric generic car 3D cutaway with all main details of an EV system illustrated.

Battery housing

EV batteries and battery housings are heavy components – often weighing over 400kg and weight reduction is facilitated using composite materials for the battery enclosures. Composites also ensure safety of the battery system is maintained – additives within the polymer matrix ensure these composites meet stringent toxicity and flame retardancy requirements, reducing risk of thermal runaway, whilst polymeric composites are also electrically insulating, reducing the risk of short circuiting. Furthermore, composite materials are known for their corrosion resistance, eliminating the requirement for additional coating processes. This helps reduce overall production costs and the carbon footprint associated with the battery housing assembly.

Electric motor

EV motors also account for a good deal of vehicle weight. Composites are being developed that are suitable for the rotor housing, stator and other components in electric motors. It has been shown that introducing composites into electric drivetrains will reduce their weight at the same time as improving the efficiency of the drive systems. Composites can also be used in the metal rotor shaft. The laminated magnet carrier can be replaced with an injection moulded part with functional separation of the torque transmission and the magnetically active part.

The metal rotor shaft can weigh almost 30% of the total rotor weight and the laminated magnet carrier around 60% so reducing the weight of these parts has significant benefits.

Interior and exterior structural components.

Composite materials are being used for structural components such as A-/ B-pillars, door reinforcement structures, and underbody panels, facilitating lightweight design of vehicle structures whilst maintaining, or even improving, vehicle safety. The use of moulded composites facilitates greater adoption of unitary construction, helping to reduce overall component numbers throughout the vehicle, and reduce the complexity of vehicle final assembly. Design of these composite structures necessitates careful consideration of the fastening methods utilised.

Understanding and solving composite fastening challenges

As composite materials grow both in range and volume of applications, the challenge to find the right fastening solution increases.

When customers move from metal to composites, as a consequence of light-weighting or for reasons of performance or design enhancement, they discover a lack of guidance or knowledge in fastening composites. This can be a major hurdle and lead to compromises and inefficiency, whether at the design, manufacture, or final assembly stage. There is no time in these environments to experiment and try things out but bigHead can provide the clarity and guidance required. We speak our customers’ language of composites and also provide a bridge to the world of fastening where the available support and expertise is sometimes more aligned to metallic or non-composite materials.

bigHead practical support for EV composite fastening

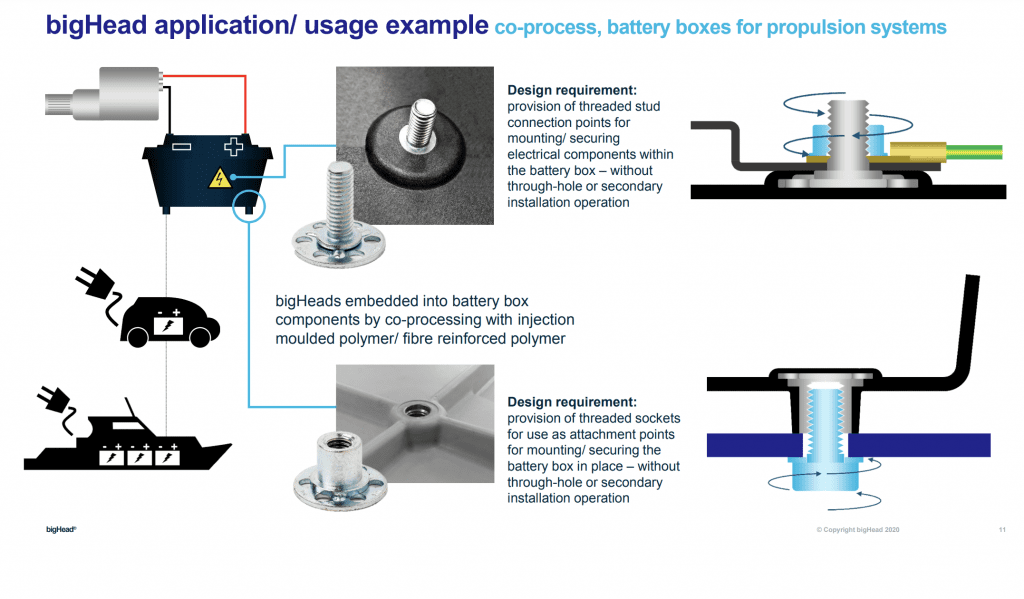

A page from one of bigHead’s downloadable TecHub documents describing an example of co-process use of bigHeads for composite fastening.

Bulkhead design

bigHead has provided valuable design and assembly advice in fastening for the production of the lightweight composite bulkhead for the latest model from a well-known USA electric vehicle manufacturer. Finding the optimum way to embed the bigHead, by including it within the bulkhead forming process, eliminated the need to spend time and money on secondary fastener installation operations. Integrating the bigHead fastener into the bulkhead manufacturing process ensured the fastener locations aligned exactly with the global component geometry and enabled an increase in the manufacturing through-put of the bulkhead. Requirements in this sector have been growing rapidly in recent years and we have the capacity to meet this demand as it develops.

Monocoque chassis

Surface bonding of bigHead fasteners provides a way to create reliable connections between composite materials and other components. There is no better example of this than the impressive all-electric Rimac Nevera super-car. This strong, powerful vehicle has a lightweight carbon fibre monocoque construction with bigHead fasteners ensuring that the composite panels and select electrical systems are held securely in place, no matter the challenges from speed and terrain conditions.

We always feel very proud that bigHead fasteners, such small components, are instrumental in the realisation of incredible engineering design.

Working with SMC

Sheet moulding compound (SMC) is being increasingly used in numerous electric vehicle applications . Working with the Cranfield Composites Centre at Cranfield University we have produced a demonstration mould tool showcasing how bigHead fasteners can be easily and reliably embedded into SMC, without any ingress of resin into or around the fixing – a notorious issue when integrating fasteners into SMC. Fasteners can be incorporated into the SMC compression moulding process without any change to the moulding parameters or process cycle time.

Ability to study composites, test fastening solutions and pass on what we learn

With bigHead’s investment in all-round expertise and state-of-the-art bespoke equipment, we are helping customers in traditional and new industry sectors get it right first time, avoiding costly and risky trial and error. Furthermore, through the Bossard Group we are spreading this expertise globally.

Ultra lightweight EV designed by Team ETA from Somaiya Vidyavihar University (SVU), Mumbai, India to compete in the Shell Eco Marathon 2023. bigHeads used in its construction.