News & insight

Global manufacturing needs global support.

At bigHead we find that global projects increasingly follow a familiar pattern; design and development in Europe where costs are high, transition to China for volume production. Such global manufacturing is complex, requiring not just the accurate transfer of knowledge and expertise but the management of different cultures and expectations. As part of the Bossard Group, bigHead is well placed to ensure that such a global transition is successful. With locations around the globe, Bossard can support global manufacturing and accompany the customer at each critical stage, ensuring that critical data and knowledge provided by specialists like bigHead is not lost along the way.

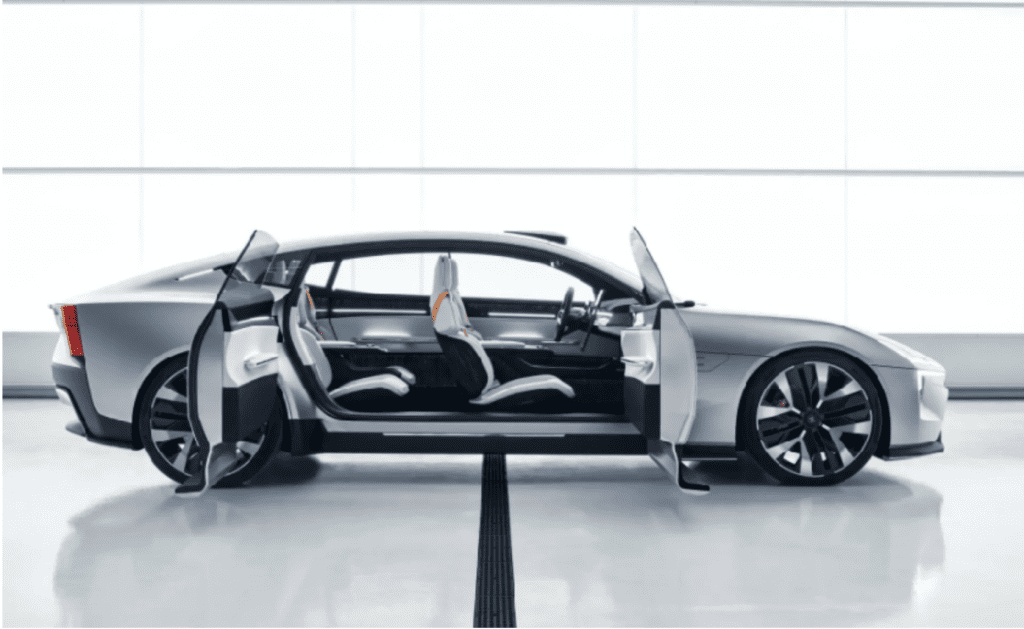

At a first design review in Sweden, bigHead was able to offer a well-known Swedish automotive OEM some tried and tested solutions for fastening the wafer-thin carbon fibre panels designed for their new EV. Once designed, the second stage was prototyping and small series production at a Tier 1 carbon fibre panel manufacturer in Italy. This company had used bigHead fasteners for many years and their experience simplified and streamlined the small series production process. Finally came transition to volume manufacture in China where local Bossard teams played an important local role, ensuring that knowledge was not lost and continuity of supply was maintained to the new production facility in Zhejiang

Membership of the Bossard Group enables bigHead to offer specialist guidance and expertise through a global platform. This unique blend of local specialism and global reach brings significant advantaged to designers and engineers.